Why make electronics from recycled plastic

The question we should all ask ourselves, and especially large companies, is: Why not do it? The result obtained is of identical quality to the virgin equivalent, with the same aesthetic and functional characteristics, where sustainability and quality go hand in hand.

First step

Faced with the challenge of improving the environmental impact of electronic products, it is easy to not know where to start. There are so many different materials, components, processes and actors in these products that the number of variables to be resolved is very large.

It has been proven that 80%

of the environmental impact of

a product can be prevented

at the design stage.

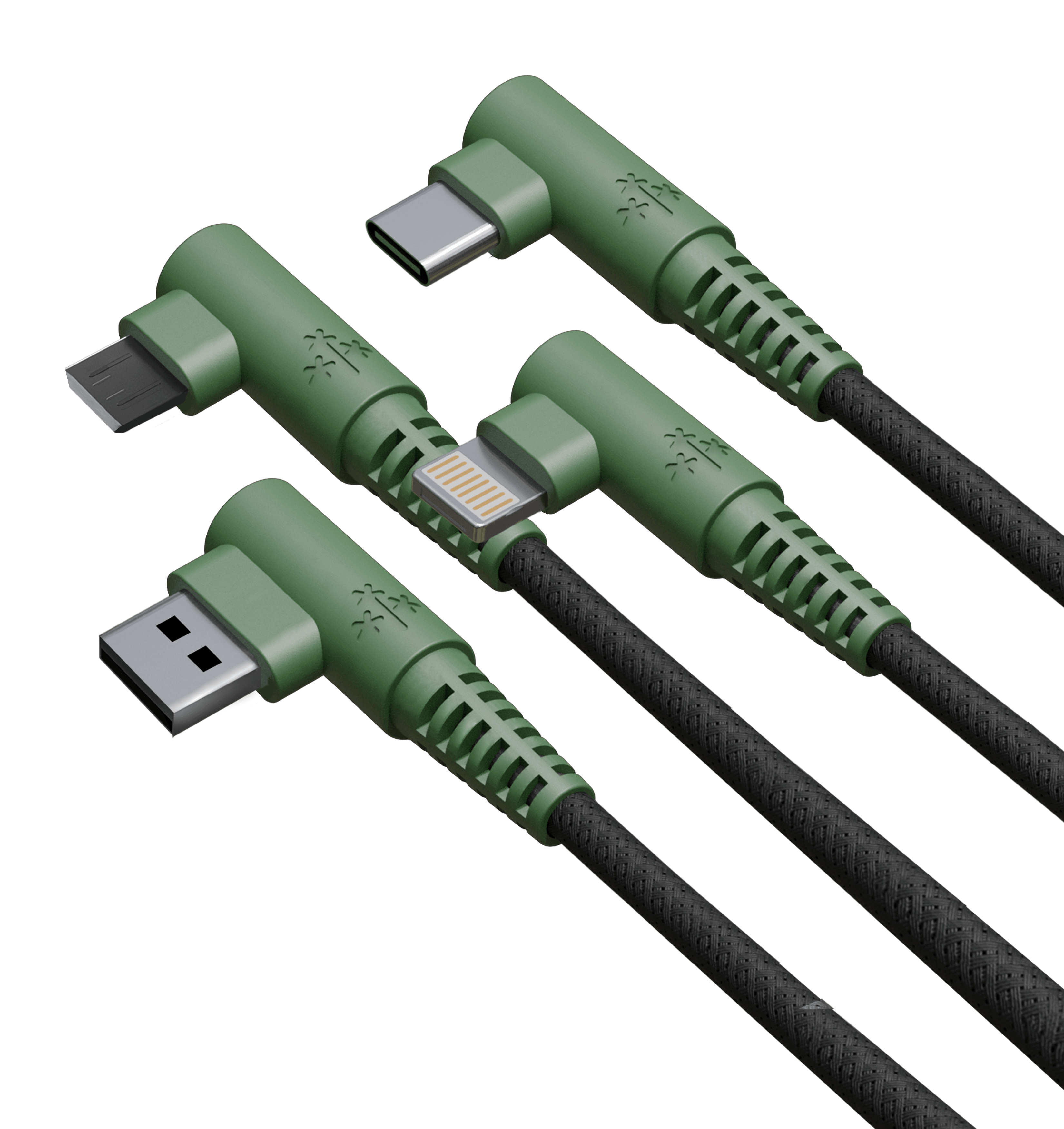

At Hune, we were quick to identify an important part of the problem: the casings and other covering materials of electronic devices generate a huge volume of waste and an immense negative impact on the environment. This presented us with a great opportunity for improvement with a series of concise decisions: the virgin plastics used in 99.99% of the electronic products on the market come from non-renewable raw materials derived from petroleum, resulting in an unsustainable practice that starts from a finite resource and whose extraction and handling generates high CO2 emissions and serious impacts on the landscape and nature. The first big decision seemed to make itself: we had to make it out of recycled plastic.

Plastic, the culprit?

Plastics are often criticized from an environmental point of view, however the biggest problem is not the material itself but the lack of information accompanied by a poor waste management policy that allows easy recovery and recycling. With a correct use (and reuse) of plastics, the environmental impact can be even less than that obtained by using alternative materials such as metals.

Every year, 8 million metric tons

of plastic end up

in our oceans.

At the start of this project, we set to work to ensure that the plastics in our products had post-consumer recycled origin certification, a milestone for a brand as young as ours.

With this we have achieved three main benefits:

- Reintroduce plastic into the production chain: there are currently more than enough plastics in circulation to produce what we need. Why are we still using virgin plastics when there is so much plastic out there waiting to be recycled? By giving them a new life we avoid deepening extractivism while preventing our lands and oceans from being flooded with post-consumer discarded plastics.

- Reducing the carbon footprint: obtaining plastic suitable for production from post-consumer recycled pellets is much easier than obtaining it from petroleum, involves less processing and lower energy consumption because it is in fact already transformed into the final material. To give an example, in the case of recycled ABS - a high quality plastic that we use in casings - the CO2 footprint is, according to our calculations, 94.08% lower than that of the virgin equivalent.

- Closing the circle on our products: recycled plastics are in turn recyclable, so that in addition to giving a second life to unused raw materials, the materials we use can be used in the future to make other products. This versatility, together with a correct management such as the one we propose in partnership with the JER - Join, Deliver & Recycle program and recycled by REMSA allows us to recover tons of plastics, components and other materials of great value to reintroduce them again.

![]()

Conscientiously made

When it comes to making decisions, we can't deny that our pulse has trembled. We analyze the specific needs of each product to find an alternative that offers the same characteristics, but with less impact. We constantly sought a balance in all the decisions we made: impact, accessibility, functionality, cost, toxicity, disposal or recycling were some of the countless variables we weighed.

Today we are convinced that making our casings and coatings from recycled plastic (accompanied by a recycling awareness and facilitation campaign in conjunction with JER/REMSA) was the best decision we could have made for our products. Nobody is perfect, and we are no exception: with a challenge as ambitious as the one we have set ourselves, there will always be improvements to be made. This is the best way we have found available to us today. We know there is still a long way to go and there will always be nuts to tighten... we are (im)perfectionists and those are the things that keep us awake at night!

What we do know today is that thanks to this decision, we have been able to reduce the emissions generated by the coating materials of our products in order to contribute as little as possible to global warming. For more specific data, the impact reports for each of our products are available on our website.

We hope we have clarified why we decided to go for these materials and that the article has been interesting for you. has it helped to change your opinion about plastics, especially recycled plastics? Your opinion is of interest to us!